Antwort Is Six Sigma useful for supply chain? Weitere Antworten – Is Six Sigma worth it for supply chain

If your company needs to increase efficiency, sending Supply Chain Professionals to Six Sigma courses for proper training can really help the bottom line – it should be considered a small investment for a large return when it comes to profitability.The Six Sigma process helps your Logistics professionals devise effective ways of achieving both perfect quality and speed simultaneously.Lean Six Sigma helps increase efficiency in several ways:

- Decreasing Order Fulfillment Time.

- Building a Responsive Supply Chain.

- Reducing Errors to Zero.

- Optimizing Order Fulfillment.

- Reducing Waste.

When should Six Sigma be used : It is used to improve the organization's products, services and processes across various disciplines, including production, product development, marketing, sales, finance, and administration. It is achieved through understanding the underlying processes, and reducing or eliminating defects and waste.

Which Six Sigma is best for supply chain management

Lean Six Sigma can help supply-chain managers make sure that their processes are not only defect-free but also focused on the customer. Businesses can achieve their goal of providing exceptional customer service by defining early in the DMAIC/DMADV processes their target audience and their needs.

Is Six Sigma actually useful : Individuals with Six Sigma certification often command higher salaries due to their specialized skills in improving business processes, reducing costs, and increasing revenue. This certification makes you more valuable to employers and clients who are willing to pay a premium for your expertise.

When employed in a logistical context, Six Sigma can identify mistakes or defects and eliminate them to reduce the amount of variability, improving the logistical process, improving the entire supply chain process.

The Six Sigma method was originally developed to combat defects in manufacturing, lowering them within an acceptable tolerance. The in-depth insight into quality control processes provided by Six Sigma analysis can be invaluable to any supply chain manager.

What is Six Sigma in supply chain management

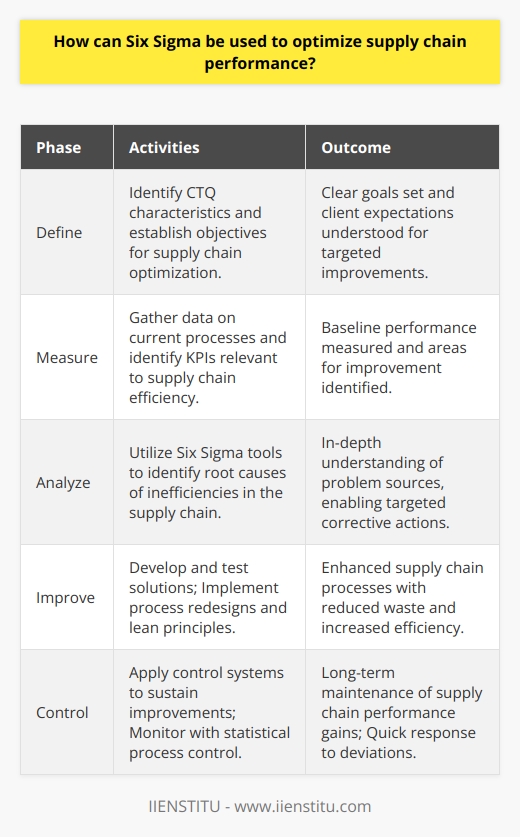

The core principle of Six Sigma is to improve process efficiency by eliminating waste and reducing variations. In the supply chain, this translates to streamlining processes, reducing lead times, and optimizing inventory management.Lean Six Sigma can help supply-chain managers make sure that their processes are not only defect-free but also focused on the customer. Businesses can achieve their goal of providing exceptional customer service by defining early in the DMAIC/DMADV processes their target audience and their needs.While Lean focuses on waste reduction/elimination, process simplification, value stream mapping, and reduce rework in the value chain. Six Sigma focuses on setting up a set of systems and people-aligned processes focusing on improving consistency of quality outcome to customers.

In reality, lean six sigma remains a powerful tool for continuous improvement especially when combined with other enabling solutions such as agile, advanced analytics and artificial intelligence.

Why Six Sigma fails in the real world : Lack of resources.

Getting sufficient numbers of “belts” trained at whatever levels is a major investment, not only in actual cash for the training, but in terms of time and adding extra work to busy managers' lives. Is it seen as too complicated In some quarters, Six Sigma is regarded as too complicated.

Why lean production and Six Sigma are so important to successful supply chain management : Lean helps increase process efficiency by focusing on speed and cost optimization. Lean ensures the stability of processes. Six Sigma focuses on quality improvement by reducing variation using statistical tools and techniques.

How is Lean Six Sigma used in supply chains in recent years

By using Lean Six Sigma, organizations can identify bottlenecks and inefficiencies in their supply chain processes, and implement solutions to improve these areas. 2. Improve their processes by reducing variability. Variability can lead to increased lead times, decreased quality, and increased costs.

Six Sigma certification is highly respected across industries. Having it on your resume demonstrates your commitment to improving your business acumen and analytical skills and your dedication to enhancing the business within which you work. This certification can help you move up the career ladder more quickly.Prevent defects

The Six Sigma method was originally developed to combat defects in manufacturing, lowering them within an acceptable tolerance. The in-depth insight into quality control processes provided by Six Sigma analysis can be invaluable to any supply chain manager.

Is Six Sigma still relevant in 2024 : If you're asking, “Is Six Sigma still relevant,” the answer is: absolutely! Many of the most cutting-edge companies, such as Microsoft and Pfizer, still use Six Sigma and Lean Six Sigma to enhance their processes, reduce errors, and optimize performance.